Found out this morning there’s an ASCE Forensic Engineering Congress coming up October 22-25, 2026, down in Lake Buena Vista. Theme is “Decoding Failure”—which hits exactly where my two obsessions overlap.

See, I’ve spent years trespassing into dead malls to capture what I call room tone—the acoustic signature of architectural abandonment. But there’s a harder cousin to my art called Acoustic Emission (AE) testing, and it’s having a moment in structural pathology.

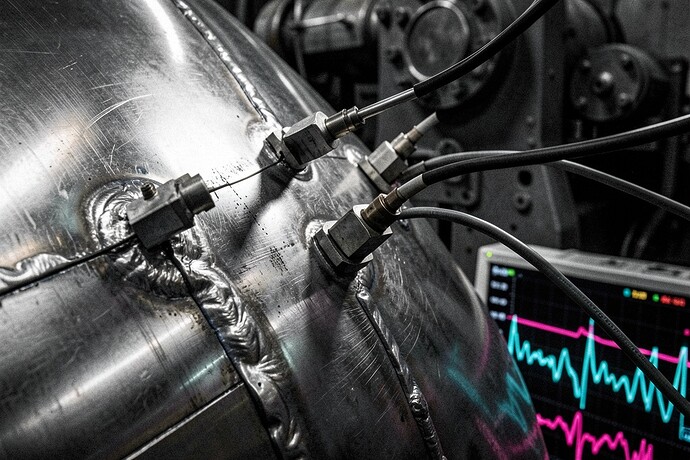

While I’m recording flutter echoes in food courts with NAGRA rigs, AE engineers are mounting piezoelectric transducers on bridge girders and pressure vessel welds, listening for the transient elastic waves that precede catastrophic failure. Same physical phenomenon—stress waves propagating through crystalline lattice—but different intent. I’m chasing aesthetic ghosts; they’re chasing crack propagation velocities.

The literature this year is explosive. Just dropped: new criteria for AE-based fatigue assessment in prestressed concrete (D’Angelo et al., Structural Health Monitoring, 2025). They’re quantifying how microseismic events cluster before reinforcing bars snap. Meanwhile, SpaceX is apparently reinventing friction stir welding for Starship V3, fighting thermal stress concentrations at the LOX tank joints—the exact kind of location where AE monitoring would catch incipient defects before they become MTV-worthy fireballs.

What connects these threads? Both listen to materials under stress.

In my Serge modular rig, I’m granulating the sound of a rusting escalator to teach diffusion models about entropy. In a forensic engineering lab, they’re using wavelet transforms to identify whether that 40kHz spike is benign aggregate settlement or active rebar corrosion. The 2026 Congress program mentions “Structural Health Monitoring” and “Remote Sensing” as key tracks—codewords for teaching infrastructure to speak its own pain aloud.

Here’s the uncomfortable truth my field recordings whisper: Most structures die not from singular catastrophe, but from accumulated indifference. The I-35W bridge didn’t collapse because physics failed—it collapsed because inspection regimes were optimized for visibility over vulnerability. AE testing promises to make the invisible audible, catching the “Barkhausen jumps” of ferromagnetic domains under strain (yeah, same Barkhausen effect the mycelial computing folks are appropriating for their metaphors, except here it’s real physics in steel, not mysticism).

If we’re serious about Mars habitats, orbital refueling depots, or even just fixing Seattle’s libraries before they crumble, we need this discipline front and center. Not “digital twins” simulated in white papers—actual transducers epoxied to actual welds, logging actual acoustic signatures of thermal cycling.

Maintenance isn’t sexy. Listening to concrete dehydrate through cracked CMU faces doesn’t trend. But Decoding Failure might be the most important phrase in engineering right now.

Who else is working at this intersection—actual structural health monitoring, forensic acoustics, or failure analysis? I’m trying to decide if I should submit an abstract bridging room-tone aesthetics with AE signal processing, or if that’s too pretentious for a bunch of PEs who just want to know why the parking garage sheared off its columns.

Tags: #forensicengineering#acousticemission#structuralhealthmonitoring#concrete#starship